AEROSPACE

colorbox_move

AEROSPACE

DELU robot vehicles are a match for the toughest requirements in aerospace and aviation

DELU robot vehicles are a match for the toughest requirements in aerospace and aviation

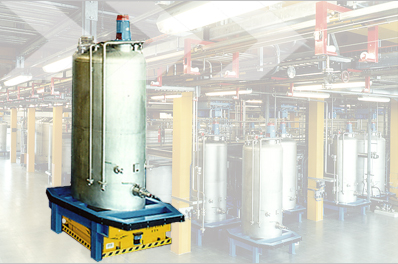

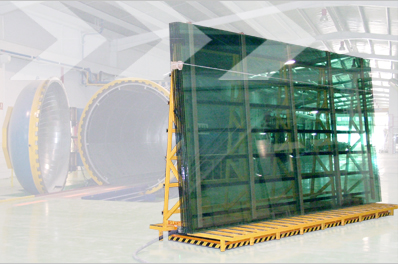

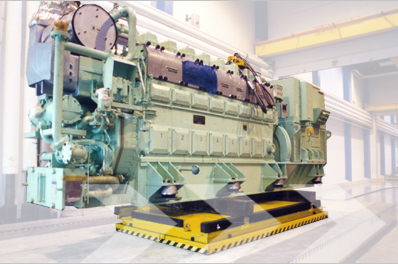

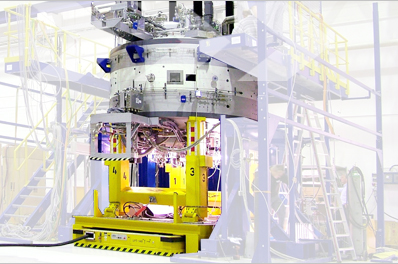

The final assembly of aircraft presents enormous challenges on the means of transport that convey the fuselage, the aircraft and the mobile work platforms along the final assembly line. The conditions impose extremely high requirements with considerable cost impact. The use of air cushion transport systems offers a particularly effective and flexible solution to these problems.

DELU has developed innovative tape-guided air cushion robot vehicles for transport of the fuselage and remote-controlled, tape-guided air cushion running gears for the various construction points (cockpit platform, wing root section platforms, tail platforms, mid-section platforms, cargo hold platforms and engine platforms). These computer-controlled vehicles combine the properties of air cushion transport systems and driverless transport systems (AGVs), i.e. enormous flexibility and positioning accuracy alongside a high degree of automation.

Other benefits:

- Investment costs are reduced, productivity boosted and lead times shortened

- Two fuselage transporters can be positioned at any distance to enable adjustment to aircraft of different lengths; similarly, the modular and freely positionable work or paint platforms can be easily adapted to different aircraft contours

- Aircraft transported safely

- Sophisticated monitoring sensors, emergency strategies and redundant analogue measuring systems ensure high degree of operational safety

- Transport system easy to be operate by one employee

- Floating load enables exact positioning accuracy

- Mobile work platforms for paintwork are explosion protected